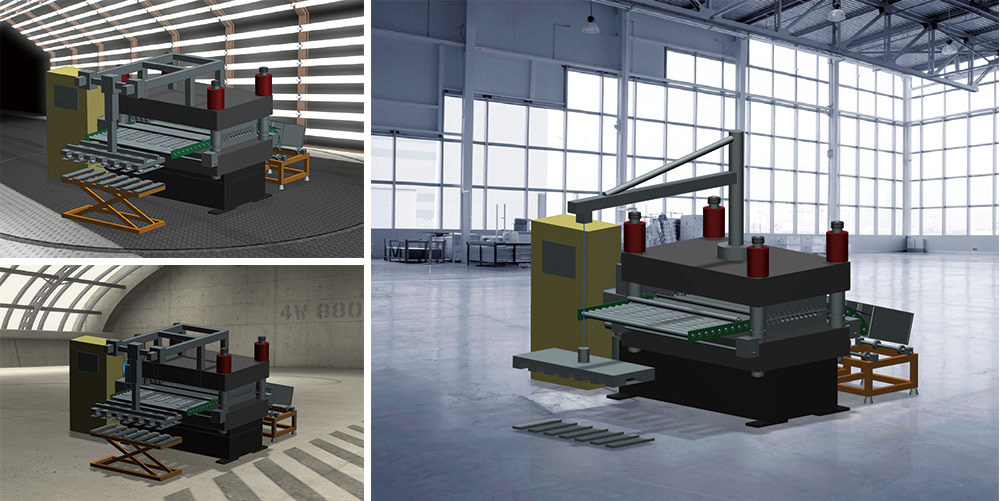

Leveling and feeding integrated machine

Rated plate thickness:

Key words:

Leveling And Feeding Integrated Machine

Basic Parameters

- Improve production efficiency

- Improve product quality

- Reduce labor intensity

- Enhance production safety

Automated loading and unloading

In the fast-paced manufacturing industry, efficiency and precision are the keys to success. The Leveling and feeding integrated machine emerges as a game-changer, offering a comprehensive solution for material processing. This innovative equipment seamlessly combines the functions of leveling and feeding, bringing numerous benefits to various production lines.

The primary function of the Leveling and feeding integrated machine is to ensure that materials, such as metal sheets, are precisely leveled before being fed into subsequent processing equipment. By eliminating warping, bending, and uneven surfaces, it guarantees that the materials meet the strict quality requirements of modern manufacturing. The leveling process is carried out with high-precision rollers and advanced control systems, which can handle different thicknesses and materials with ease.

The feeding function of this integrated machine is equally remarkable. It accurately and continuously supplies the leveled materials to the next stage of production. With adjustable feeding speeds and precise positioning, it can adapt to different production rhythms and processing needs. Whether it's for stamping, cutting, or other manufacturing operations, the Leveling and feeding integrated machine ensures a smooth and uninterrupted material flow.

One of the significant advantages of the Leveling and feeding integrated machine is its high degree of automation. It reduces the reliance on manual labor, minimizing human errors and improving production consistency. Workers only need to set the parameters according to the production requirements, and the machine will complete the leveling and feeding tasks automatically. This not only increases productivity but also enhances workplace safety.

Another benefit is its versatility. It can be integrated into various production lines, including automotive manufacturing, home appliance production, and metal fabrication. In the automotive industry, for example, it can handle large-scale metal sheet processing, ensuring the precision of parts and reducing production costs. In home appliance manufacturing, it helps produce high-quality metal components with consistent quality.

Moreover, the Leveling and feeding integrated machine is designed for easy maintenance. Its modular structure allows for quick replacement of components, reducing downtime in case of breakdowns. Regular maintenance can keep the machine in optimal working condition, ensuring long-term stable performance.

Product Features

Solution

Immediate Consultation

Please leave a convenient contact number, we will have a special customer service personnel to confirm and arrange your message.