Understanding Sheet Metal Straightener Machines: Essential Tools in Metal Fabrication

In the realm of metal fabrication, precision and efficiency are paramount. One crucial tool that plays a vital role in achieving these goals is the sheet metal straightener machine. This device is specifically designed to correct the warping and bending of metal sheets, ensuring that they meet the required specifications for further processing or fabrication. Understanding how sheet metal straighteners operate can significantly benefit those involved in manufacturing and metalworking industries.

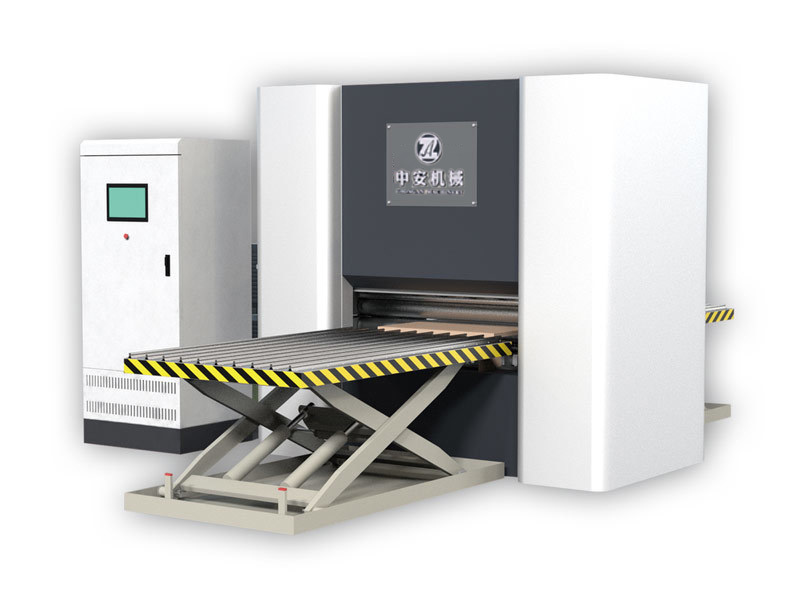

A sheet metal straightener machine typically consists of a series of rollers and guides. These components work together to apply pressure and manipulate the metal sheets into a flat and uniform shape. The process generally involves feeding the warped or bent sheet through the machine. As the metal passes through the rollers, the pressure exerted helps to realign the material, reducing any imperfections. This capability is crucial, as even minor inconsistencies in metal sheets can lead to significant challenges during subsequent phases, such as cutting or welding.

The advantages of using a sheet metal straightener machine extend beyond just achieving flatness. One of the key benefits is the improvement in overall productivity. With the ability to quickly and effectively straighten metal sheets, manufacturers can reduce downtime associated with manual adjustments and rework. This efficiency not only speeds up the production process but also enhances the quality of the final products, allowing businesses to maintain high standards.

Moreover, these machines are versatile and can accommodate a variety of metal types, including steel, aluminum, and copper. This flexibility makes them invaluable to shops that handle multiple materials or different thicknesses of metal. The ability to adjust the settings on a sheet metal straightener machine allows operators to customize the process, ensuring optimal results for each specific job.

In addition to efficiency and versatility, investing in a sheet metal straightener machine can lead to cost savings in the long run. By minimizing waste from imperfect materials and reducing the need for extensive rework, businesses can enhance their profitability. Furthermore, the improved quality of the final products can lead to increased customer satisfaction and repeat business, further contributing to the bottom line.

In summary, sheet metal straightener machines are essential tools in the metal fabrication industry, offering significant benefits in terms of efficiency, quality, and cost-effectiveness. Understanding their operation and advantages can empower businesses to make informed decisions about their manufacturing processes and ultimately enhance their competitiveness in the market. Whether you are a small shop or a large manufacturing facility, incorporating a sheet metal straightener machine into your workflow can be a game changer.

Related News

undefined